On the direct electrification of steam

(max out heat pumps) [Feb 2024]

This post focuses on the direct electrification of steam production in industry and touches on solar and heat pumps to get there. Reach me at dm@duncanmcmillan.xyz for comments.

TLDR: Solar will continue to cheapen rapidly, heat pumps will continue to win, and lots of industrial sites may mistakenly electrify their steam supply rather than maximise heat pump capacity. I think the gap between ‘factories as they exist today’ and ‘factories as you would build them today’ has never been greater. I think a tricky retrofitting problem is underway.

On solar

Firstly solar. I am no expert and there are great papers and resources available on solar PV’s rise. I highly recommend Ramez Naam’s postr1, and his writing in general. I have tried to pull the key facts from Ramez’ post and some others. The high-level summary is that solar will continue to win - and continue to beat the expectations of institutions like the IEA - and will drive to down electricity costs everywhere, including industry.

![IEA's poor forecast performance [ref 1]](images/Picture1.png)

It’s amazing how poor the supposed authority on climate has been at predicting the expansion of solar PV install capacity, panel efficiency and cost1. It’s a trend also seen in academic papers, which continue to ignore the wave of electrification coming in industry. Almost all long-term energy modelling papers fail to account for the exponential rise of solar, and therefore come out pessimisticr2.

![Solar cost forecasts [ref 1]](images/Picture2.png)

This is the key chart. Solar cost's decrease is decades ahead of schedule. It seems academia have continuously failed to grasp the exponential nature of solar PV’s rise, generally failing to account for Wrights law2. Solar’s learning rate of ~30% has been remarkably robust historically. Wind power also has an impressive learning rate of ~10% and ~20% for offshore and onshore respectively, which will also contribute to the cheapening of electricity in windy geos like the UK.

![Wind and solar learning rates [ref 3]](images/Picture3.png)

![Solar cost forecasts out to 2050 [ref 1]](images/Picture4.png)

![Global region adjusted solar cost forecasts out to 2050 [ref 4]](images/Picture5.png)

These projections suggest a massive wave of electrification is coming to industry. But can this cost reduction really continue? I don’t see why not.

There are barriers to the continued build out of solar, but a lot of these arguments end up being somewhat parochial because they have always been arguments against solar, and despite this solar has held its incredible learning rate. A strong argument against solar would acknowledge the historical learning rate and give a new explanation for why now the learning rate will flatline. An example argument of this kind is to say, “yes solar’s build out to this point has been incredible, but in the near future solar and wind’s intermittency issues will reach some sort of tipping point and overwhelm the grid and build out will stall”. This would be a good argument if battery capacity was not being built out at an even quicker rate3.

On steam electrification

What would radically cheap electricity mean or industry?

I guess that industry will shift not just to cheap electricity geos, but also in product, with electricity dominant processes and products outcompeting fuel reliant processes. We will also see industry facing the temptation to directly electrify their steam production, which is a mistake I will focus on here.

Why is this a mistake? Because it is a waste of work.

There are many solutions available today to either replace a fuel burning boiler for an electric boiler, or to replace the burner and tubes with resistive coils, and these solutions are very close to 100% efficient in terms of energy, and are often sold on these terms, replacing a ~90% energy efficient fuel boiler with a ~100% energy efficient electric boiler.

If electricity is so cheap what’s so bad about that? Because we can do better!

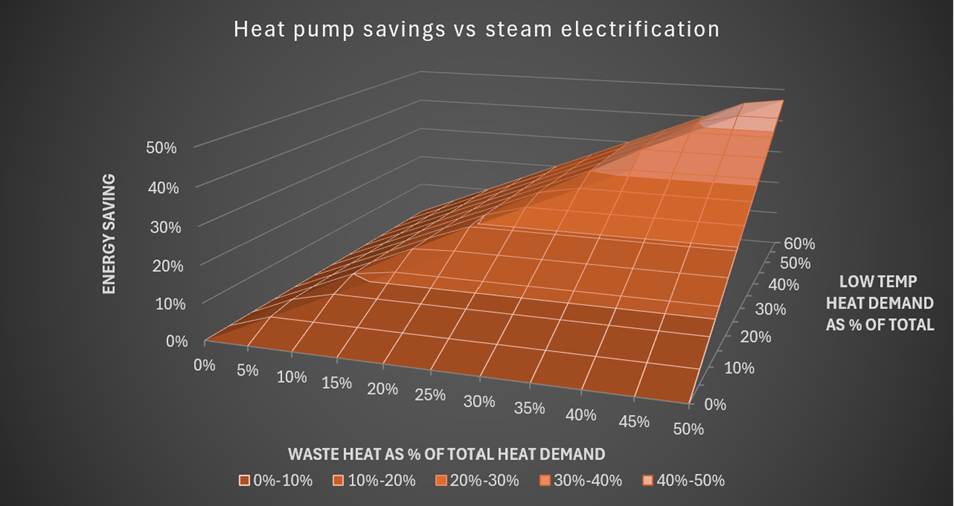

Direct electrification of steam only makes sense where there is no low temperature4 demand and no waste heat5 from the process, which is very rare. Generally, in industry there are some low temperature users and some waste heat pulled from the process. Where this is true a heat pump should be installed.

The exact numbers are dependant on the steam loop efficiency and the heat pump coefficient of performance (COP) but the shape is always the same6. This is why the ~100% efficiency figure for direct electrification is too flattering, as a heat pump will be say ~4x as energy efficient due to the COP. Even with cheap electricity, there is a massive opportunity cost in directly electrifying steam production where a heat pump could do.

Another way of highlighting the waste inherent in electrifying steam is by looking at the exergy of the system. Exergy is the ability to carry out useful work. Electricity’s energy and exergy values are equivalent, 100kW of electricity can provide 100kW of work. This is not the case for steam. Yes, 100% of the energy from the electricity is transferred to steam, but only ~28% of the useful work is. On the other hand, a heat pump is ~50% exergy efficient, depending on the COP7.

On steam companies

This logic can also be applied to the question: “Should a steam focused company acquire a heat pump solution?”

If you agree that a large chunk of industrial processes use steam to ultimately service both high temperatures and low temperatures, and create significant waste heat, then it makes sense for those industrial processes to install a heat pump and narrow their steam boiler use purely to high temperature demands. This process is already underway and will continue with the development of heat pump solutions and the decrease in electricity price relative to fuel. What we are describing is a general reduction in steam boiler capacity requirement, and a marginal de-steaming for hot water loops8. It therefore makes sense for a steam focused company (particularly a boiler manufacturer) to acquire or develop a heat pump business. In general, the issue is that today steam boilers are over installed from a thermodynamic perspective. This is because the historic relative price of fuel to electricity has been too low, and industrial heat pumps were too costly. Historically even with the COP it has been cheaper to use fuel rather than electricity.

If renewables really do continue their dramatic price reductions industry will undergo electrification en masse. Sites built to burn fuel and use steam extensively today will face a tricky retrofitting dilemma. One way to highlight this is to picture the gap between how a company’s assets/factories exist in reality today, in terms of layout, design and processes, and how we would build them today as a brand-new plant. The gap between existing factories today and ideal new designs is very large, and larger than has historically been the case.

Steam has been the heat transfer solution of choice since the industrial revolution and will continue to be used widely, albeit with a de-steaming of low temperature uses where this has not already happened. Steam boilers will be outcompeted by heat pumps as electricity becomes cheaper and high temperature heat pumps mature as a technology. In addition to the retrofitting issues touched on here we will see an array of new products and processes made viable by incredibly cheap electricity. More to come.

Footnotes:

1 This chart reminds of the FED inflation estimatesr5.

2 Wrights law is the empirical finding that a given technology’s cost reduces (improves) exponentially with production or scale out. In other words, every doubling of install capacity brings a constant % reduction in cost. This % is referred to as the learning rate, as the primary mechanism of the improvement comes from industry ‘learning’ to produce the technology cheaper as it scales.

3 see Casey Handmer’s great blogsr6r7 on this subject. Like Ramez Naam’s I recommend all of Casey’s writing.

4 low temperature = could be serviced by a heat pump. Think ~90degC.

5 Regarding waste heat, imagine a process which has a heat requirement but somehow encapsulates that energy entirely in the product or emits the waste heat in a form that is completely impractical to capture. These processes are very rare. In reality, sending effluent to drain above ambient temperature is the norm, as is having massive cooling towers to reject unwanted heat.

6 This exact chart comes from assuming a COP of 4.5 and a perfect steam loop. Also note that I am only looking at waste heat from the process and ignoring potential nearby water sources.

7 Also note an exergy perspective highlights why fuel boilers are actually very efficient. Many fuel boilers are very close to their Carnot efficiency. It’s not fair to say that a 100% efficient electric boiler is better than a 90% efficient fuel boiler. The electric boiler is wasting exergy!

8 This doesn’t mention the development of high-temperature heat pumps which directly compete for steam boiler temperaturesr8.

References:

r1 Solar’s future is insanely cheap, Ramez Naam

r2 DOI 10.1016/j.energy.2017.01.017

r3 Cheap renewables growth, Our World in Data

r4 DOI 10.1038/s41467-023-41971-7

r5 Inflation expectations, John Cochrane

r6 Battery onslaught, Casey Handmer